Are you in search for the best air compressor for irrigation? With so many options available, it can be hard to decide which one is right for you.

Are you in search for the best air compressor for irrigation? With so many options available, it can be hard to decide which one is right for you.

Here’s a comprehensive guide to help you make an informed choice and get the most from your purchase. You’ll quickly discover how to find an air compressor that meets your needs and budget.

Air compressors have a wide range of uses in agriculture, with irrigation one of the most important. Air compressors are necessary to power drip, sprinkler and spray irrigation systems, to efficiently move water and nutrients to plants for optimal growth.

When deciding on an air compressor for irrigation, you’ll want one that provides reliable and consistent pressure at the correct flow rate. Additionally, factors such as size, noise level and power source should also be considered when selecting an appropriate compressor for your operation.

The information provided in this guide is designed to help you choose the best air compressor for irrigation needs.

Definition of an Air Compressor for Irrigation

An air compressor (also known as a pump-tank) is an essential piece of equipment for irrigating land. It converts electrical energy into mechanical energy to pump water through pipes and sprinkler heads. In order for an air compressor to be effective, it must be able to handle the required pressure levels, utilize the correct size pipe and fittings, and be set up with the proper controls for optimal performance.

Different types of air compressors are available depending on the application. Some types are piston-driven pumps, rotary screw compressors, centrifugal compressors, diaphragm pumps and hydraulic systems. Depending on their application, some air compressors also require additional filtration or special maintenance due to improper use or environment conditions such as high dust levels. Additionally, additional accessories or attachments may be necessary in order to maximize water delivery efficiency.

A quality selection of irrigation air compressors will come with various features that provide durability and guarantees regardless of which type you select.

Importance of Choosing the Right Air Compressor for Irrigation

Choosing the right air compressor for your irrigation system is essential to ensure smooth, consistent operation and cost-effective maintenance. A number of considerations must be taken into account, including the flow rate of your system, the size and performance of the compressor you need, and the environmental conditions where it will be used.

The flow rate is determined by the amount of pressure required in order to adequately water plants; this information is typically available in product literature or through your contractor. Once you know what pressure is necessary, you can then consider how large an air compressor should be used to achieve that flow. The size of the compressors are usually categorized by horsepower (HP) or horsepower per gallon (HPG) ratings; typically 0-2 HPG for residential systems and 0-3 HPG for commercial systems.

Another factor affecting air compressor choice is atmospheric conditions such as temperature and altitude. This can affect performance capabilities due to reduced air density, so it’s important to select a compressor that is suited to intense conditions such as hot deserts or high mountainsides where a larger capacity model may be necessary. Additionally, compressors need certain accessories including filters, tanks and regulators applied appropriately for efficient operation in variable settings.

Finally, choosing an energy efficient model should also be taken into account in order to reduce operational costs. Many new models are specifically designed for conservation which can provide large savings over time due their increased life expectancy and low power consumption outputting more air with less energy inputs; this ultimately contributes both financially and environmentally towards smart irrigation practices.

Understanding Air Compressor for Irrigation

Understanding the key components of an air compressor used in irrigation will help you better choose which system is best suited to meet your desired application. The main components of an effective irrigation system include a reservoir, pump, compressor, and distribution lines.

The compressor is responsible for providing the air pressure needed to move the water around in order to create the desired effect. The most common type of compressors used for this purpose are piston-type or rotary type compressors. For example, a piston-type compressor uses a series of pistons connected to crank arms to compress the air while a rotary type utilizes two interlocking vanes and an impeller wheel to achieve the same purpose. Each type has its own unique advantages which should be taken into consideration based on your equipment requirements.

When considering the best compressor for your application, size plays a vital role in overall performance. A larger-sized unit will require more energy and will provide higher output pressures that can be used for more demanding systems such as those utilizing micro sprinkler or drip systems with long runs of irrigation tubing. Smaller units are more suited for shallow well applications or residential home gardens.

The recommended discharge pressure ratings may vary from manufacturer to manufacturer but it’s advisable to look for one capable of supplying at least 25 PSI so that it can deliver more than enough power needed when operating multiple heads simultaneously during peak usage hours. Additionally make sure that your compressor is able to handle both continuous and intermittent duty cycles as this will ensure optimum performance when using large amounts of water during peak season times when maximum flow rate is desired quickly and efficiently without overworking your system components.

Definition of an Air Compressor

An air compressor is a device that converts power from an electric motor, generator, engine or other source of mechanical power into potential energy contained in pressurized air. The energy contained in pressurized air can be used to power pneumatic tools and irrigation systems. Air compressors can be used to pump water and other fluids, as well as powered tools. With the addition of an irrigation system to an existing agricultural production facility, farmers are able to quickly adapt their operations for greater efficiency and versatility.

When choosing an air compressor for use in agricultural operations, it’s important to consider several factors. First, the size and capacity of the compressor must match the demands of the job that it will be used for. For irrigation purposes, a good rule of thumb is to choose a model that is rated for 25% more than the maximum output your system will require since higher pressures are sometimes needed for optimal performance.

It’s also important to consider how much noise a compressor will produce during operation so as not to disturb livestock or wildlife. Many models now have noise reduction technology built-in which helps lower operating sound levels so they are less intrusive on animals or people nearby. Finally, make sure that any chosen models meet safety requirements according to relevant building codes or agricultural regulations depending on where you live.

Components of an Air Compressor

An air compressor for irrigation consists of four essential components:

- The compressor

- The motor

- The filter

- The controller

The Compressor – The main job of the compressor is to convert outside air into a pressurized form, which is then stored in a tank or reservoir. It is usually driven by an electric motor or internal combustion engine. The type and power of the engine will determine the capacity and output of your air compressor.

The Motor – This component powers the compression process. Motors for air compressors are typically electric or gasoline powered. Electric motors are more efficient but require more regular maintenance and tend to be slightly more expensive than gasoline-powered models, however they come in various sizes and configurations to suit different needs.

The Filter – This component filters debris from entering your system from outside sources like dirt, dust and other impurities.. The filter performs an essential role in preventing wear and tear on your system components by trapping these contaminants before reaching internal parts of your machine.

The Controller – This device regulates when and how much compressed air flows through your system according to demand demands Its settings can be adjusted manually or it may be connected to sensors that regulate pressure or transmit signals automatically if there is a change in temperature or humidity levels in your soil profile.

Factors to Consider Before Choosing an Air Compressor

When you’re shopping for an air compressor for irrigation, there are a few key factors to consider. Every compressor model is different and each one has its own advantages and disadvantages. Knowing what you need out of your machine will help you make the best decision possible when it comes to selecting an air compressor for your irrigation system.

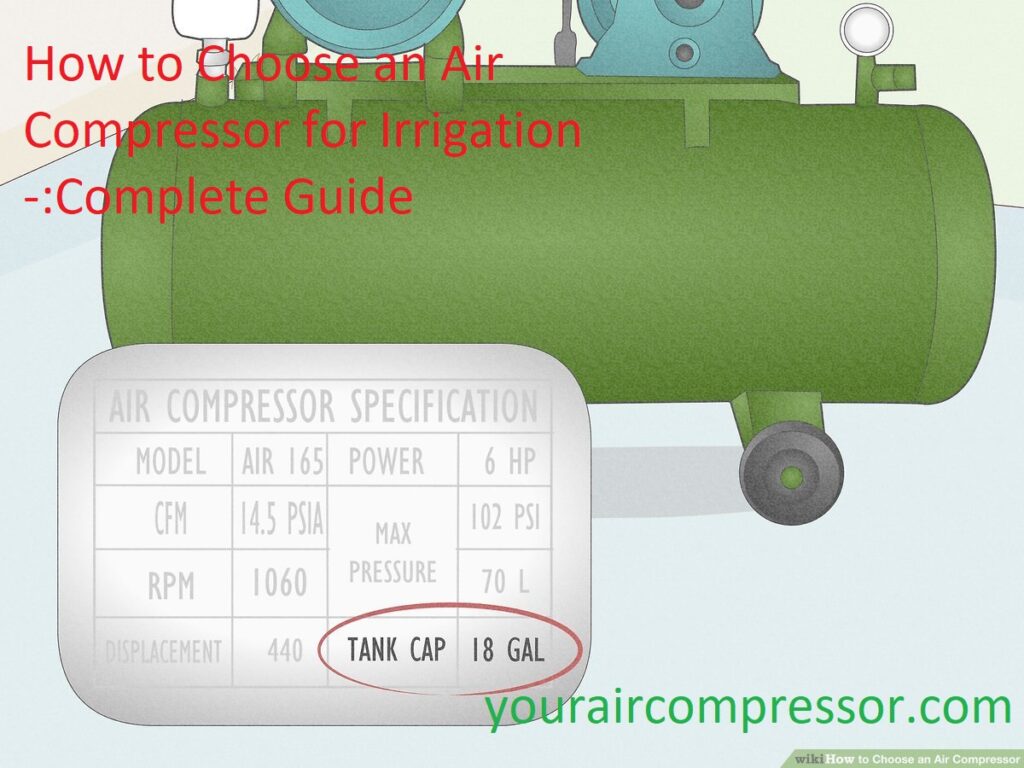

The three main factors that are important to consider when purchasing an air compressor include the horse power, tank size and the type of pump that the compressor is using. The more powerful the motor, the stronger and more consistent a pressure will be provided by the unit. A larger tank size means that more air can be stored – resulting in less frequent stops, while a pump with good quality components will increase its life span.

It’s important to remember that every situation is different and so you should research accordingly before making any purchase decisions. If possible, try to find reviews on any particular product before committing to a purchase. Feedback from previous customers can be surprisingly helpful in guiding your decision-making process.

The Size of Your Irrigation System

The size of your irrigation system is the first factor to consider when you’re choosing an air compressor for irrigation. There are many different sizes of air compressors that you can choose from, but the biggest ones are generally more suitable for large systems. For example, a larger system might require a compressor that’s rated in horsepower equal to or greater than 8.5, and will typically range up to 15 horsepower.

If you have a smaller system, a smaller and less powerful compressor may be enough, as long as it has sufficient capacity and output pressure to operate all the components of your irrigation system. Consider the type of equipment needed to operate your particular system—if it uses high-pressure nozzles or other specialised tools they may require larger compressors.

In any case, make sure that you select an air compressor that has enough capacity and output pressure to power all necessary components in your irrigation system—making sure not to buy more than is necessary as this can lead to higher costs associated with powering and operating the unit over time.

The Type of Irrigation System

The type of irrigation system you use is particularly important in the selection of an air compressor. For instance, pivot systems have high water pressure needs due to their more compact field, while dripper and sprinkler systems may need lesser pressure since they also operate at lower frequency levels. Depending on your irrigation system, you need to choose either a two- or three-stage air compressor (two stages for small areas or three stages for larger areas). Note that direct coupled compressors tend to be more efficient than belt-driven ones.

It’s also important to understand the layout and requirements for your irrigation system when determining the size of your compressor. If you need a system with a large flow rate, then it’s advisable to opt for larger framed machines rather than smaller ones. Generally speaking, small flows require smaller motors, while larger flows may require greater capacity motors and multi-cylinder units. Additionally, consider whether you’re dealing with an open circuit or closed loop when determining what type of compressor best suits your needs; typically open flow applications call for rotary screw compressors and closed loop systems are better suited for reciprocating piston models.

The Air Requirements of the Irrigation System

The air requirements of an irrigation system will depend on the type of equipment and how it is utilized. If you are using a single-stage pump, then the amount of air needed to drive the system will be determined by the size of the compressor and its motor rating. For example, a five-horsepower compressor with a 10-gallon tank can deliver about 5 cubic feet per minute (CFM) of movement at an appropriate pressure range (most likely between 70 and 120 PSI).

However, if you are using a larger irrigation system with multiple pumps or sprinklers, then you will need to accurately estimate the total airflow needed by adding up all components in order to ensure that your chosen compressor can support them. Additionally, these air requirements should be taken into account when selecting an intermediate-duty or heavy-duty air compressor—especially if you plan on running several sprinklers or pumps at one time.

How to Choose the Right Air Compressor for Irrigation

Air compressors are an essential part of many irrigation systems and can make irrigation more efficient and cost-effective. However, choosing the right air compressor for your needs can be tricky. To make sure you get the best performance from your air compressor, it is important to consider the following factors:

- Usage – The type of use for which you need your air compressor should determine the type of compressor you purchase. Irrigation needs usually require lightweight, low PSI compressors that are designed to handle frequent starting/stopping cycles.

- Power Source – There are several different power sources available for air compressors, including gasoline, diesel, electric and natural gas. Each has its own set of pros and cons that should be considered before purchasing an air compressor.

- Capacity – The capacity (or size) of an air compressor is determined by how much compressed air it can store at one time. The amount of compressed air needed depends on the size and complexity of irrigation systems.

- Pressure Rating – Pressure rating refers to how much pressure each individual tank can maintain when full with compressed air. It is important to choose a pressure rating that will not overpower the requirements of your irrigation system or risk breaking components in the system due to overpressurization.

By considering these factors when choosing an irrigations-specific air compressor, you can ensure that you get long-lasting service from a reliable piece of equipment for use in your operation for many years to come!

Identify Your Needs

When selecting an air compressor for irrigation systems, it is important to understand your specific needs. An air compressor’s power requirements, as well as the type of air compressor needed, must be determined before a purchase can be made. You’ll need to consider several key factors when trying to decide which type and size of air compressor is needed for your project.

First, you will need to consider the hose length of your irrigation system. Typically, longer hose length calls for more power from an air compressor and vice versa; shorter hose lengths require less power from an air tank. Also keep in mind that you need maximum efficiency when irrigating large areas; this might mean investing in a larger capacity and horsepower motor.

Additionally, you must determine the necessary PSI rating of your irrigation lines is also critical; a higher rating requires more horsepower and capacity from an air tank than a lower rating would. You should also consider any additional accessories like spray guns and valves that you may use with your system; these will have an effect on the size and output requirements of an airflow pressure tank too. Finally, examine any existing irrigation supplies such as clamps or brass connectors that require installation; these might necessitate upgrades or changes to the type or size of your selected unit.

Choose the Right Type of Air Compressor

When selecting an air compressor for irrigation, it’s important to understand the different types of compressors that are available and to select the one that is best suited for your needs. Generally speaking, there are two main categories of air compressors: rotary screw and reciprocating (or piston).

Rotary screw compressors use intermeshing rotors to separate rapidly moving air particles, creating a vacuum and then compressing them. They are typically used in larger-scale operations and require a greater initial investment than other types of compressors because they’re more expensive to install and service. However, they also provide higher efficiency ratings due to their ability to obtain consistent flows of compressed air at high pressures. This makes them ideal for irrigation systems requiring higher amounts of pressurized air.

Reciprocating or piston air compressors work by transferring mechanical energy from the crankshaft into high pressure compressed air. This type of compressor is most commonly used in smaller scale applications due to their low maintenance requirements, affordability, and low energy consumption levels. Additionally, their size allows for ease in installation and portability when needed.

Conclusion

The right air compressor can be an invaluable asset to any irrigation system. Whether you’re looking for a large, commercial-grade machine or something smaller and more budget-friendly, there are plenty of options out there to choose from.

When shopping for an air compresssor for irrigation, consider the size of your application, the power necessary to run it, the available features and the cost. By taking these factors into account and comparing different models based on your own needs and preferences, you can easily find a compressor that best suits your purpose.

With some guidance from experienced professionals and careful shopping around, you should be able to find exactly what you need for a price that fits your budget.

FAQ

What size air compressor do I need for irrigation system?

The size of the air compressor needed for an irrigation system depends on several factors such as the number of sprinkler heads, the length of the irrigation system, and the desired pressure.

How do I know what size air compressor I need?

To determine the size of air compressor needed, you need to consider the required pressure and CFM (cubic feet per minute) for the tools or equipment being used. The CFM requirement for the equipment should be listed in the product manual or specifications.

How much pressure does an air compressor need for sprinklers?

The pressure needed for sprinklers varies depending on the specific type and model of sprinkler. However, a typical range for sprinklers is between 30 and 50 PSI (pounds per square inch).

How much pressure do I need for irrigation?

The pressure needed for irrigation also depends on the specific system and its components. A pressure of around 40 PSI is typically sufficient for most irrigation systems.

How many CFM air compressor do I need?

The required CFM for an air compressor depends on the tools or equipment being used. To determine the necessary CFM, you need to check the product manual or specifications for each tool and add up the requirements.

How much air compressor capacity in 1hp?

The air compressor capacity in 1hp can vary depending on the specific model and manufacturer. However, a typical range is between 3 and 4 CFM at 90 PSI.

What compressor is good for sprinkler blowout?

A compressor with a minimum of 5 CFM at 90 PSI is typically good for sprinkler blowout.

What is the difference between 1/4 and 3/8 air compressor fittings?

The difference between 1/4 and 3/8 air compressor fittings is their size. A 1/4 fitting has a diameter of 0.25 inches, while a 3/8 fitting has a diameter of 0.375 inches. Generally, larger fittings can handle higher volumes of air.

What is CFM vs PSI air compressor?

CFM (cubic feet per minute) is a measure of the volume of air that an air compressor can deliver, while PSI (pounds per square inch) is a measure of the pressure of the air delivered. Both CFM and PSI are important considerations when selecting an air compressor.

What is CFM vs PSI?

CFM (cubic feet per minute) is a measure of the volume of air that a tool or equipment requires to operate, while PSI (pounds per square inch) is a measure of the pressure of the air delivered. CFM and PSI are both important considerations when selecting an air compressor to ensure that it can meet the requirements of the tool or equipment being used.

see also…

- Best onboard air compressor 2023

- Best oil free air compressor 2023

- Best jump starter with air compressor 2023

- Best High Pressure Air Compressor 4500 Psi 2023

- Best harbor freight air compressor2023