Do you want to find out how an air compressor works? Don’t get baffled by think of complex technical terms and machines. This article is here to make understanding air compressors simpler and easier for you.

Do you want to find out how an air compressor works? Don’t get baffled by think of complex technical terms and machines. This article is here to make understanding air compressors simpler and easier for you.

Get ready to acquire an in-depth knowledge about the working principles of air compressors.

An air compressor is a tool used to create pressurized air from a volume of ambient air. This pressurized air is then used to power various tools, such as pneumatic screwdrivers, paint guns and nailers. Air compressors come in many sizes and shapes and can be powered by electricity, gas or diesel engines.

In order to understand how an air compressor works, it is important to first understand the principles of pressure and volume. Pressure refers to how much force is placed on a given area. Volume refers to the amount of space that an object takes up or the total cubic feet taken up by all the molecules within a space.

As with any machine, air compressors rely on some specific physical principles you should be familiar with if you plan on using or maintaining one: Boyle’s Law, Charles’ Law and Bernoulli’s Principle. Boyle’s Law states that the pressure of a gas increases in proportion with its decrease in volume while Charles’ Law states that temperature and pressure are related; when temperature increases, pressure will also increase. Finally, Bernoulli’s Principle relates the speed at which fluids move through pipes inversely with total energy; faster moving fluids have lower energies than slower moving fluids. We will explore each of these physical laws in more detail later on this guide as we continue our exploration of how an air compressor works.

Definition of an Air Compressor

An air compressor is a device that increases the pressure of air by reducing its volume. This is done by drawing in atmospheric air which contains numerous atmospheric molecules and compressing it into an enclosed space, resulting in higher pressure. The main purpose of an air compressor is to convert power (usually generated by an electric motor, diesel engine, gasoline engine, etc.) into potential energy stored in pressurized air, which can then be used to do a variety of tasks such as powering pneumatic tools, blowing up balloons and powering some automotive brakes.

An air compressor works on the principle of converting one form of energy into another. In this case, it takes electrical power (from an electric motor or other source) and converts it into mechanical energy that is used to compress the atmosphere within a storage tank or container, thus increasing the overall pressure inside that storage chamber or tank. This increase in pressure enables greater force when connecting with other objects or systems with the use of pneumatic tools such as spray guns. The technology employed for operation and control purposes depend on the type and size of the device used – ranging from manual switches for small compressors to more sophisticated computer-aided controlling systems for industrial large scale air compressors.

Importance of Understanding the Working Principles of an Air Compressor

A thorough understanding of the working principles of an air compressor is essential for a range of industrial and other applications. Air compressors are used to generate energy in the form of compressed air, which can be utilized for a variety of purposes such as driving machinery, painting, construction work and more. The principles are important for ensuring that the correct pressure is generated inside the compressor.

Various factors determine how much pressure and flow rate will be produced from an air compressor including:

- Size and type of compressor

- The number and types of devices connected to it

- Type of medium being compressed

- Pressure levels within the compressor

- Operating temperature.

Having a good understanding of these factors can help you make sure that you buy the best air compressor for your specific needs. Furthermore, it is important to have regular maintenance performed on your air compressor in order to ensure that it operates at optimal efficiency without facing any unexpected technical problems. Additionally, understanding the working principles can also help you apply pressure at different levels according to specific needs. Different applications require different pressure ranges; therefore it is important to ensure that you select the correct capacity for your application needs.

Overview of the Content

This guide outlines a comprehensive overview of air compressors and their working principles, providing information about how air compressors operate, their components, types of compressors, performance ratings, and safety considerations. It also contains helpful tips on troubleshooting as well as frequently asked questions.

We will begin with the basics – what an air compressor is and how it works. We will then take a deep dive into the components that make up an air compressor such as its motor, gauge, regulator, tank and the types based on its design. Additionally, we’ll look at common performance ratings to ensure you have the right size compressor for your needs – PSI (pounds per square inch), Cubic Feet Per Minute (CFM) , Voltage/Amperage etc.

Finally we’ll cover some important safety considerations that should be taken into account when using an air compressor correctly in order to avoid any dangerous or damaging situations. In addition to our content here we suggest doing research on particular makes/models of air compressors in order to gain a full understanding when making your next purchase decision or finding out more about any related topics or problems you may have.

Air Compressor Maintenance

Air compressor maintenance is an important part of ensuring the safe and reliable operation of your equipment. Regular maintenance can help detect potential problems early, reducing the risk of machinery breakdowns and costly repairs. It also helps to maximize performance and reduce energy costs.

To ensure that your compressor is running safely and efficiently, it is important to keep up with periodic maintenance routines such as lubrication, filter checking, leak testing and general problem-solving. Here are some key components to consider when developing a maintenance schedule:

- Lubrication: Proper lubrication helps minimize friction between moving parts, reducing wear on components over time. Automated systems can be used to meter out lubricants, or manual lubrication can be applied at most 3 months or every 5,000 hours – whichever comes first for most professional applications.

- Filters: When working with compressed air it’s important to maintain a high level of cleanliness in the system; this means replacing all filters regularly as they trap dirt particles which can damage other components. Air filters should be replaced every 6 months or 8,000 hours—whichever comes first.

- Leak Testing: We recommend leak-testing your compressor once a month; this includes checking all hoses and connections for leaks as well as inspecting compression fittings for rust or corrosion build-up that could cause greater problems down the road. Additionally, if you’re dealing with hazardous materials like gas or solvents it’s important to check for any possible cross contamination monthly too! Lastly always make sure any exhaust ducting from systems is not leaking into occupied spaces by testing pressure drops periodically throughout system runs.

Regular Inspection and Cleaning

Regular inspection and cleaning of an air compressor is essential for optimal performance. Inspections should be performed routinely to ensure the proper operation of the compressor and to keep it working safely and efficiently. During an inspection, all components of the unit should be inspected for signs of wear or damage, such as leaks, loose fittings, debris buildup in the lines or tanks, and cracked or broken parts. Ensuring that exterior surfaces are clear from dirt, dust, grime, oil and moisture will help ensure a longer life for the unit as well.

The air intake filter should also be checked during regular inspections. Air passing through the filter will not only prevent particles from entering the machine but help to reduce noise levels during operation as well. If clogged filters are not cleared periodically they can lead to significantly reduced airflow which in turn affects performance as well as running costs over time due to higher energy consumption rates.

The oil level in either a piston or rotary screw compressor should also be checked during inspections and topped up when necessary according to manufacturer’s recommendations. Excess oil in either type can cause foaming or frothing in a tank which then reduces air pressure available when needed. Insufficient oil can cause engine components such as bearings and other moving parts to wear prematurely due to too much heat being generated inside due to friction caused by low lubrication levels.

Lastly any available hoses or other connecting carriers should also be examined closely for any damage before being put back into operation after every use.

Lubrication and Oil Changes

Lubrication is an essential element of the functioning of any air compressor. It helps prevent wear, keeps the temperature in check, and protects internal components from being exposed to extreme temperatures. An air compressor must use a type of oil that is specially designed for it, and it must be constantly monitored to ensure that levels remain correct.

Oil needs to be added regularly to keep an air compressor working correctly. The manufacturer should detail in their user manual the frequency at which oil changes need to occur. Depending on the model, this could be after every 25-50 hours of work, or every month during winter months when temperatures are cooler. They may also detail specific instructions such as oil type and how much should be added per fill.

Various methods can be used for changing the oil, depending on the model; some use sight glasses while others have dipsticks or even digital indicators that make it easier to know when an oil change is necessary. You should take special care when disposing of used motor oils as these can cause significant environmental damage if not disposed correctly according to laws in your area or country.

Safety Tips for Operating an Air Compressor

It is important to be aware of safety precautions when using an air compressor. Some general safety tips to keep in mind include:

- Make sure the work area is well-ventilated and free from combustible materials.

- Make sure the cord and plug are in good condition before use, and that it has a grounded three-prong plug.

- Listen for any strange noises that may indicate a problem, as these can be indicative of malfunctioning parts.

- Use dry filters and coalescing filters to ensure that no moisture enters the air line, which could damage the compressor or any downstream components.

- Carefully read all labels and instructions on all the components being used with the air compressor before beginning work.

- Always wear eye protection and gloves when handling any type of machinery or electrical devices, such as an electric motor or power tool.

- Closely follow all safety procedures provided by manufacturers regarding start-up, shut-down, maintenance, safety features such as pressure relief valves, etc.

- When connecting hoses or other tools, be sure to secure connections with clamps or other retaining devices so they do not become loose during operation.

Proper Use of Personal Protective Equipment

Whenever you are dealing with a powered machine, like an air compressor, it is essential to put on proper personal protective equipment (PPE). This includes eye protection to protect your eyes from any flying particles that might be kicked up by the machine. You should also wear ear protection, as the compressor can get loud and cause hearing damage if you are operating near it for long periods of time.

It is highly recommended to wear gloves as well, so that you don’t accidentally injure your hands. Clothes should also be considered—long sleeved shirts and tight-fitting jeans are ideal. Wearing tight-fitting clothing helps protect against any debris or dust that could be kicked up during the operation of the compressor and helps provide some insulation in case the machinery gets hot while in use.

In addition, you should ensure that your shoes are sturdy to help prevent slipping if any liquid spills out of the machine while running. Finally, a dust mask can help keep you safe from accidental inhalation of particles during operation, so make sure this piece of PPE is worn at all times while using an air compressor.

Safe Operation of Controls and Valves

It is important to always read and understand the manufacturer’s instructions on how to safely operate the compressor before attempting to begin using it. It is also essential to be familiar with all of the controls and valves on the unit, and how they work together.

Controls and valves for compressed air typically include a main pressure control, a valve for controlling the amount of service line pressure, an adjustment valve (or series of adjustment valves) used to regulate ambient operating pressure, safety relief valves, blowoff valves, unloading valves and check valves.

Main Pressure Control: This control is used to adjust the maximum “allowed” working pressure in a system. It should not exceed any applicable governmental or industry established safe working pressures (in most cases this will be between 80 – 150 PSIG). The user should always ensure that the Main Pressure Control setting fits within this limit before attempting any operation with an air compressor.

Service Line Pressure: A valve that regulates service line pressure will often accompany a main control system as another layer of protection from potentially dangerous high pressures within a compressed air distribution system. These controls can allow extra burst capacity when a job or tool may need it without having to adjust the main operating pressure each time (e.g., if you are frequently switching tools).

Ambient Operating Pressure: Depending on your particular application requirement, you may have an adjustment valve available for adjusting ambient operating pressures within your installation. Ambient temperatures often cause compression issues stemming from final discharge pressures being less than anticipated values due to thermal expansion of air molecules under higher temperatures or lower densities in colder environments resulting in greater volumes at equal pressures thus leading to lower final discharge values than expected; this can also have an impact on end product quality issues arising from expansion problems in either direction so adjustable units are important when project requirements include varying temperature ranges or humidity levels.

Working Principles of an Air Compressor

An air compressor works on the principle of positive displacement. This means that it compresses air into a smaller volume by reducing the size of its containment chamber. This process is repeated as many times as required to reach a desired pressure. During this compression process, heat is generated and must be expelled from the system in order for it to work efficiently.

The efficiency and power of an air compressor are typically determined by the CFM capability of the machine, or cubic feet per minute, which is defined as how many cubic feet of air can be displaced through the machine’s output per minute. The more CFM capability it has, the more powerful it will be at producing larger volumes of compressed air. Additionally, most compressors will also come with ratings for free airflow rate (FCFM) and maximum airflow rate (MCFM). Both variables are important when selecting a compressor.

When selecting which type of compressor to use, you should also consider its motor size and tank capacity. The motor size directly affects how much output power is available from it while tank capacity determines how much compressed air can be stored in reserve for future use without having to run it continuously. In addition, noise levels should also be taken into account for safety reasons when operating a machine in a loud environment such as a factory floor or field workshop location.

Compression Cycle

The Compression Cycle is the process of increasing internal pressure of air in a compressor. During the cycle, air is drawn into the compressor, and as it is compressed, its temperature rises.

The cycle starts when air enters the intake valve at atmospheric pressure and then passes through an inlet filter that removes dust and other particulates before it enters a cylinder where it is compressed. During compression, pressure raises continually and temperature increases until it reaches the maximum cut off point determined by the setting of a regulation device.

At that point, an outlet valve opens to relief excess pressure within the chamber and then release hot exhaust gas back into atmosphere. This process continues over and over until work demand on compressor reduces or stops completely.

Pressure Switch Operation

A pressure switch helps to regulate the output of the compressor by learning what pressure is needed to operate correctly. It is set in the factory with a pre-determined cut-in/cut-out pressure. The difference between the two points is usually 10 or 20 psig (pounds per square inch gauge ).

When the air tank drops below the cut-in setting, a signal will be sent to the compressor motor to turn on, and when it exceeds the cut-out pressure, it will turn off. In basic terms, as we use compressed air out of our tanks, the pressure drops and when it reaches a certain point (the cut-in) our switch turns back on and replenishes our tank’s air volume and returns us to full capacity.

This process continues until we reach the cut-out point where our tank is once again full of air and doesn’t need any more air to be added. At this point, our switch turns off so we don’t overfill our tank or cause any potential damage from too much pressure building up inside it.

Conclusion

In conclusion, air compressors are versatile and useful tools that come in a variety of shapes and sizes. Understanding the working principle of an air compressor is the key to mastering the tools available.

It is important to consider factors such as temperature, pressure, and CFM when making your decision on what type of compressor you need for your application. Additionally, having knowledge about compressors can help you choose the right one for your project.

When using an air compressor for a specific task it also helps to think about the features that are best suited for that job as well as consider other factors such as size and cost. Compressed air can be used in many ways and understanding how an air compressor works will enable you to take full advantage of this valuable resource.

FAQ

What are the 2 principles of air compressor?

The two principles of air compressor are compression and delivery.

What is the working principle of 3 stage air compressor?

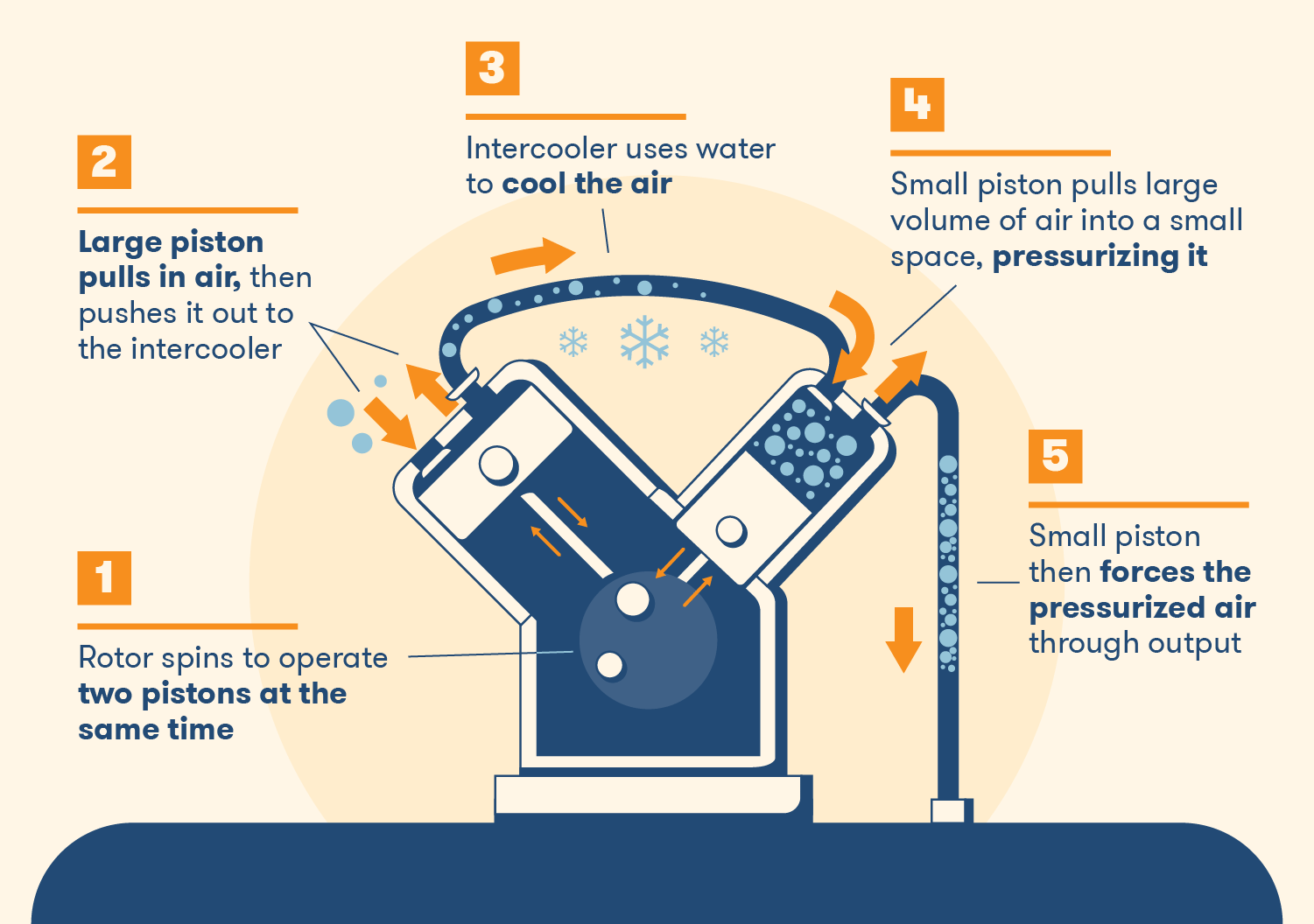

The working principle of a 3 stage air compressor involves compressing air in three stages using intercoolers between each stage to cool the air and increase its density, which leads to higher efficiency.

What is the working principle of compressor in thermodynamics?

The working principle of a compressor in thermodynamics involves increasing the pressure of a gas by reducing its volume, which is done by using mechanical work.

What is the main function of air compressor?

The main function of an air compressor is to convert power into potential energy stored in pressurized air, which can then be used for various applications such as powering pneumatic tools or filling air tanks.

What is the compressor unit principle?

The compressor unit principle involves using a mechanical device to increase the pressure of a gas by reducing its volume, which results in the compression of the gas.

Which law is used in air compressor?

The gas laws, particularly Boyle’s law and Charles’ law, are used in air compressors to explain the relationship between the pressure, volume, and temperature of gases.

What are the basic principles of air pressure?

The basic principles of air pressure include the fact that pressure is exerted equally in all directions, increases with depth, and decreases with altitude.

What are the prcincipal types of compressors?

The principal types of compressors include reciprocating, rotary screw, centrifugal, and axial compressors.

What are the 4 components of compressor?

The four components of a compressor are the motor, compressor pump, pressure switch, and tank.

What are two purposes of a compressor?

Two purposes of a compressor are to increase the pressure of a gas and to store potential energy in pressurized air for use in various applications.

see also…

- Best Air Compressor For Spray Painting 2023

- Best air compressor for sandblasting 2023

- Best air compressor for RV 2023

- Best air compressor for roofing nailer 2023

- Best Air Compressor For Off Roading 2023